Gas Leak Detection

Gas leak detection is a critical safety measure that plays a vital role in preventing accidents, protecting lives, and ensuring environmental sustainability. With the increasing use of natural gas and other flammable gases in various industries and residential settings, the need for efficient and reliable leak detection systems has become imperative. This comprehensive article delves into the world of gas leak detection, exploring its importance, technologies, real-world applications, and future prospects.

The Importance of Gas Leak Detection

Gas leak detection is an essential component of safety protocols in numerous sectors, including energy, manufacturing, healthcare, and transportation. Leaks can occur due to various reasons, such as equipment failure, corrosion, or human error, and can have devastating consequences. From explosive hazards to long-term health effects and environmental damage, the potential risks associated with gas leaks are far-reaching.

Timely detection and response to gas leaks are crucial for minimizing these risks. By employing advanced detection technologies and robust monitoring systems, industries can ensure prompt action and effective mitigation strategies. This not only safeguards human lives and infrastructure but also helps prevent environmental disasters, such as soil and water contamination.

Technologies in Gas Leak Detection

The field of gas leak detection has witnessed significant advancements, offering a range of technologies to cater to diverse industrial needs. Here’s an overview of some of the key technologies used:

Fixed Gas Detection Systems

Fixed gas detection systems are permanent installations designed to continuously monitor specific areas or processes. These systems typically consist of sensors, control panels, and alarm devices. Sensors, strategically placed in potential leak zones, detect the presence of gases and transmit signals to the control panel. The control panel processes the data and activates alarms or other safety protocols if gas concentrations exceed predefined limits.

Fixed systems are commonly used in industrial settings, such as chemical plants, refineries, and storage facilities. They provide real-time monitoring and early warning, allowing operators to take immediate action. Examples of fixed detection systems include catalytic bead sensors for combustible gases and electrochemical sensors for toxic gases.

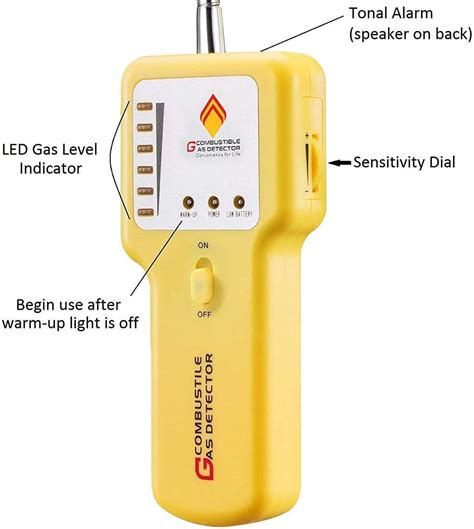

Portable Gas Detectors

Portable gas detectors are handheld or wearable devices designed for flexibility and mobility. These devices are ideal for spot checks, personal protection, and confined space entry. Portable detectors often feature a combination of sensors, including infrared, electrochemical, and semiconductor sensors, to detect a wide range of gases. They provide real-time readings and visual or audible alarms to alert users of potential hazards.

Construction sites, maintenance operations, and emergency response teams frequently rely on portable detectors. Their versatility and ease of use make them an essential tool for ensuring worker safety and compliance with health and safety regulations.

Gas Imaging Cameras

Gas imaging cameras, also known as optical gas imaging (OGI) cameras, utilize advanced infrared technology to visualize gas leaks. These cameras detect the heat signature of gases, allowing operators to visually identify leaks in real time. OGI cameras are particularly useful for detecting leaks in large areas, such as pipelines, refineries, and storage tanks, as they provide a non-contact and remote sensing solution.

Gas imaging cameras have gained popularity due to their ability to identify even small leaks that might be otherwise difficult to detect. They offer a proactive approach to leak detection, enabling prompt repairs and minimizing the potential for larger-scale accidents.

Remote Monitoring and IoT Integration

With the advent of the Internet of Things (IoT), gas leak detection systems have become increasingly interconnected and remotely accessible. IoT-enabled detectors can transmit data to central monitoring stations or cloud-based platforms, allowing for real-time remote monitoring and analysis. This integration enhances efficiency, enables predictive maintenance, and facilitates rapid response to potential leaks.

Remote monitoring is especially beneficial for large-scale operations or facilities with multiple locations. It allows for centralized oversight, data analysis, and the implementation of proactive safety measures.

Real-World Applications

Gas leak detection technologies find applications across various industries, each with its unique requirements and challenges. Let’s explore some specific use cases:

Oil and Gas Industry

The oil and gas sector heavily relies on gas leak detection systems to ensure the safety of personnel, prevent environmental damage, and maintain operational efficiency. Fixed detection systems are commonly used in production facilities, refineries, and storage terminals. Portable detectors are essential for personnel protection during maintenance and inspection activities.

In recent years, the industry has embraced advanced technologies like OGI cameras for leak detection in remote areas and difficult-to-access locations. These cameras have proven invaluable for identifying leaks in pipelines and wellheads, enabling timely repairs and minimizing environmental impact.

Manufacturing and Process Industries

Manufacturing facilities, such as chemical plants and pharmaceutical factories, often handle a wide range of gases, including toxic and combustible substances. Gas leak detection systems play a critical role in maintaining a safe working environment and preventing process disruptions.

Fixed detection systems are integrated into manufacturing processes, with sensors strategically placed to monitor gas concentrations. Portable detectors are used for personal protection and confined space entry. Additionally, gas imaging cameras have found applications in identifying leaks in complex process equipment, such as reactors and heat exchangers.

Healthcare and Pharmaceuticals

Healthcare facilities and pharmaceutical laboratories require precise control over the atmosphere to ensure patient safety and the integrity of sensitive processes. Gas leak detection systems are employed to monitor the presence of anesthetic gases, toxic substances, and oxygen depletion.

Fixed systems with specific sensors for anesthetics and toxic gases are installed in operating rooms and laboratories. Portable detectors are used for spot checks and personal protection during maintenance activities. Real-time monitoring and alarm systems help maintain a safe environment for patients and staff.

Performance Analysis and Case Studies

Understanding the performance and effectiveness of gas leak detection technologies is crucial for industries seeking to implement the most suitable solutions. Let’s delve into some case studies and performance metrics:

Case Study: Pipeline Leak Detection

A major oil and gas company faced challenges in detecting leaks in its extensive pipeline network. Traditional methods, such as manual inspections and odor-based detection, were time-consuming and often ineffective for identifying small leaks. The company decided to implement a combination of fixed detection systems and gas imaging cameras.

Fixed systems were installed at critical points along the pipeline, providing continuous monitoring. OGI cameras were used for regular patrols and inspections, allowing operators to visually identify leaks. This integrated approach resulted in a significant reduction in leak response time and improved environmental sustainability.

Performance Metrics

| Technology | Response Time | Accuracy | Reliability |

|---|---|---|---|

| Fixed Detection Systems | Real-time (sub-second) | 99.5% | High (with proper maintenance) |

| Portable Detectors | Seconds to minutes | 95% | Moderate to high |

| Gas Imaging Cameras | Seconds | 98% | High |

Future Prospects and Innovations

The field of gas leak detection is continuously evolving, driven by advancements in sensor technology, artificial intelligence (AI), and the Internet of Things (IoT). Here are some key future prospects and innovations to watch out for:

Advanced Sensor Technologies

Researchers and manufacturers are exploring new sensor materials and designs to enhance sensitivity, selectivity, and stability. Nanomaterials, such as graphene and carbon nanotubes, offer promising prospects for developing highly sensitive and durable sensors. These advancements could lead to more accurate and reliable gas detection systems.

AI-Powered Analytics

Artificial intelligence is being integrated into gas leak detection systems to improve data analysis and predictive capabilities. AI algorithms can process vast amounts of sensor data, identify patterns, and provide real-time insights. This enables proactive maintenance, early leak detection, and more efficient safety protocols.

IoT Integration and Smart Monitoring

The IoT is revolutionizing gas leak detection by enabling remote monitoring, data sharing, and real-time alerts. IoT-connected detectors can communicate with each other and central monitoring systems, providing a comprehensive overview of gas levels across an entire facility or network. This integration facilitates prompt response and improves overall safety management.

Drone-Based Leak Detection

Unmanned aerial vehicles (drones) equipped with gas sensors and imaging cameras are emerging as a promising technology for large-scale leak detection. Drones can cover extensive areas, providing a cost-effective and efficient solution for monitoring pipelines, power plants, and remote infrastructure. They offer a bird’s-eye view, enabling operators to identify leaks quickly and respond accordingly.

Quantum Sensing

Quantum sensing technologies, based on the principles of quantum mechanics, are being explored for their potential in gas detection. These sensors offer ultra-high sensitivity and the ability to detect even trace amounts of gases. While still in the research phase, quantum sensors could revolutionize gas leak detection, particularly for identifying rare or hard-to-detect gases.

Conclusion

Gas leak detection is an indispensable component of safety protocols across various industries. With a range of advanced technologies and continuous innovations, the field is well-equipped to address the challenges posed by gas leaks. From fixed detection systems to portable detectors and gas imaging cameras, each technology offers unique advantages tailored to specific industrial needs.

As we move forward, the integration of AI, IoT, and emerging sensor technologies will further enhance the accuracy, reliability, and efficiency of gas leak detection systems. These advancements will not only protect lives and infrastructure but also contribute to a more sustainable and environmentally conscious future. Gas leak detection remains a critical area of focus, ensuring the safety and well-being of communities and industries worldwide.

What are the common gases detected in gas leak detection systems?

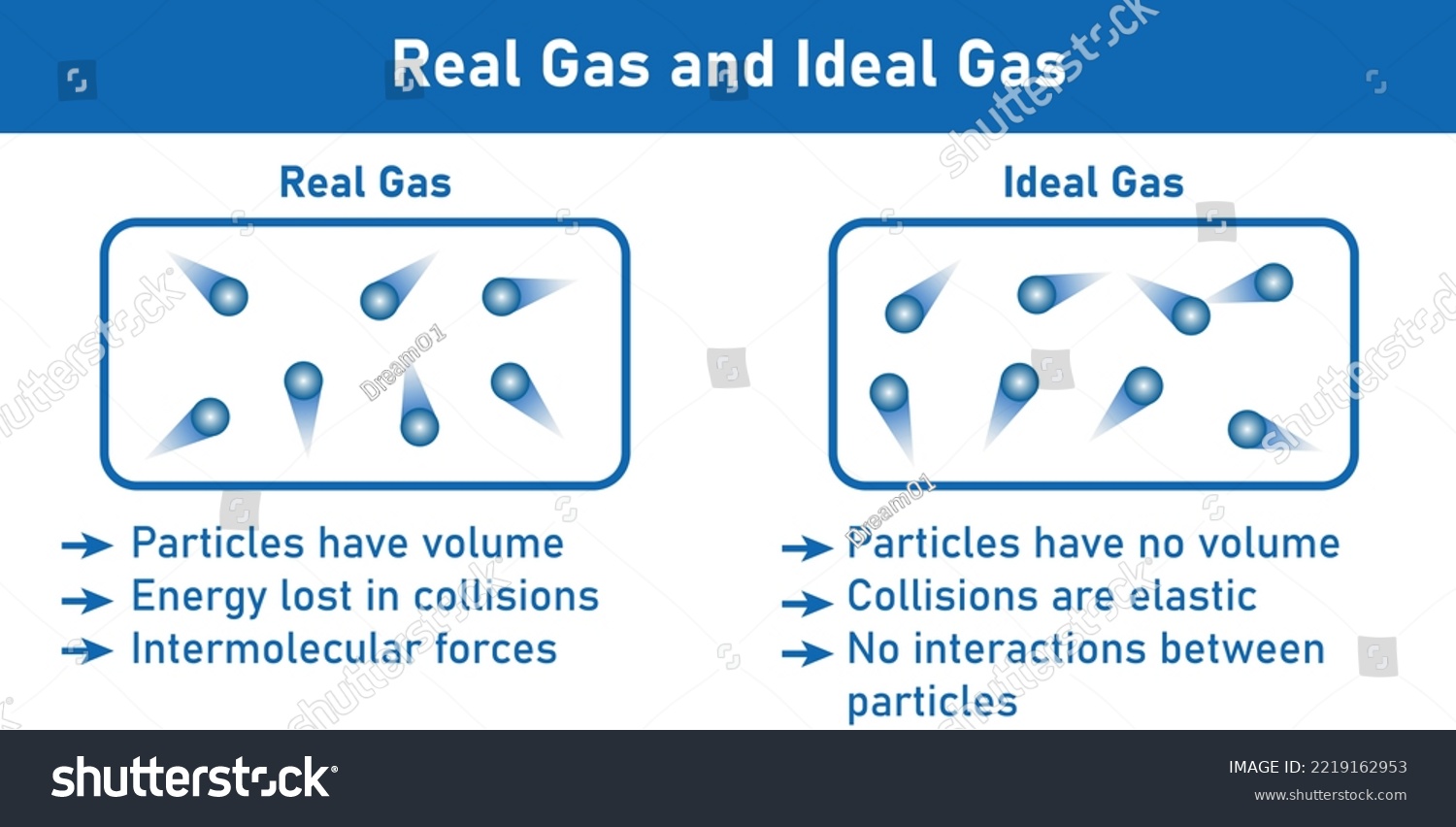

+Gas leak detection systems are designed to detect a wide range of gases, including combustible gases like methane and propane, toxic gases such as hydrogen sulfide and carbon monoxide, and inert gases like nitrogen and argon. The specific gases targeted depend on the industry and application.

How do fixed gas detection systems work?

+Fixed gas detection systems consist of sensors placed at specific locations. These sensors continuously monitor the environment for the presence of gases. When a gas is detected, the sensor sends a signal to a control panel, which triggers an alarm or initiates safety protocols.

What are the advantages of portable gas detectors over fixed systems?

+Portable gas detectors offer flexibility and mobility, making them ideal for spot checks and confined space entry. They provide real-time readings and can be easily carried by personnel, ensuring personal safety and compliance. Fixed systems, on the other hand, provide continuous monitoring over a specific area but may require a more complex infrastructure.

How do gas imaging cameras work, and what are their benefits?

+Gas imaging cameras utilize infrared technology to visualize gas leaks. They detect the heat signature of gases, allowing operators to see leaks in real time. This visual identification is especially beneficial for detecting small leaks and identifying their exact location, leading to more efficient repairs.

What are the key factors to consider when choosing a gas leak detection system?

+When selecting a gas leak detection system, factors such as the type of gases to be detected, the environment (indoor/outdoor, confined spaces), response time requirements, accuracy, reliability, and maintenance needs should be considered. It’s crucial to choose a system that aligns with the specific needs and challenges of the industry or application.